All Categories

View All >-

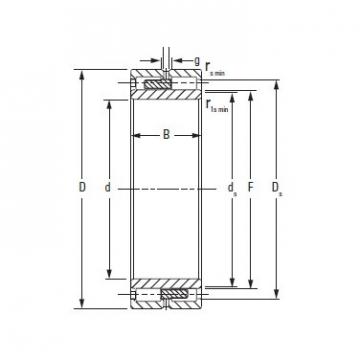

Thermal Speed Ratings - Grease TIMKEN NNU4152MAW33 Two-Row Cylindrical Roller Radial BearingsSee More>

Thermal Speed Ratings - Grease TIMKEN NNU4152MAW33 Two-Row Cylindrical Roller Radial BearingsSee More> -

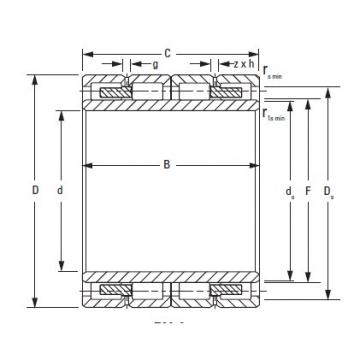

O.D. D TIMKEN 250RY1681 Four-Row Cylindrical Roller Radial BearingsSee More>

O.D. D TIMKEN 250RY1681 Four-Row Cylindrical Roller Radial BearingsSee More> -

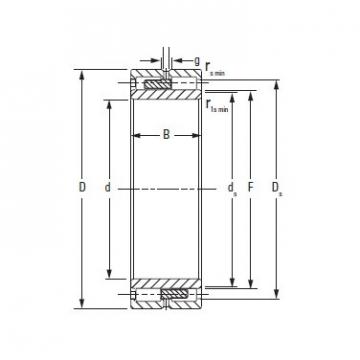

Chamfer rsmin TIMKEN NNU49/900MAW33 Cylindrical Roller Radial BearingSee More>

Chamfer rsmin TIMKEN NNU49/900MAW33 Cylindrical Roller Radial BearingSee More> -

60 mm x 110 mm x 28 mm Manufacturer Name NTN NU2212G1 Single row Cylindrical roller bearingSee More>

60 mm x 110 mm x 28 mm Manufacturer Name NTN NU2212G1 Single row Cylindrical roller bearingSee More>

Featured Products

Our Manufacturer with main products: Two-Row Cylindrical Roller Radial Bearings, Four-Row Cylindrical Roller Radial Bearings, Cylindrical Roller Radial Bearing

-

60 mm x 130 mm x 31 mm Fatigue limit load, Cu NTN NU312G1 Single row Cylindrical roller bearing

60 mm x 130 mm x 31 mm Fatigue limit load, Cu NTN NU312G1 Single row Cylindrical roller bearing

-

60 mm x 110 mm x 28 mm Manufacturer Name NTN NU2212G1 Single row Cylindrical roller bearing

60 mm x 110 mm x 28 mm Manufacturer Name NTN NU2212G1 Single row Cylindrical roller bearing

-

F ZKL NUJ1060 Single row Cylindrical roller bearing

F ZKL NUJ1060 Single row Cylindrical roller bearing

-

60 mm x 110 mm x 28 mm E NTN NJ2212ET2X Single row Cylindrical roller bearing

60 mm x 110 mm x 28 mm E NTN NJ2212ET2X Single row Cylindrical roller bearing

-

80 mm x 140 mm x 26 mm Manufacturer Name NTN NJ216C3 Single row Cylindrical roller bearing

80 mm x 140 mm x 26 mm Manufacturer Name NTN NJ216C3 Single row Cylindrical roller bearing

-

45 mm x 85 mm x 19 mm Fatigue limit load, Cu NTN NU209EG1 Single row Cylindrical roller bearing

45 mm x 85 mm x 19 mm Fatigue limit load, Cu NTN NU209EG1 Single row Cylindrical roller bearing

-

70 mm x 150 mm x 51 mm Characteristic rolling element frequency, BSF NTN NJ2314ET2XC3 Single row Cylindrical roller bearing

70 mm x 150 mm x 51 mm Characteristic rolling element frequency, BSF NTN NJ2314ET2XC3 Single row Cylindrical roller bearing

-

75 mm x 130 mm x 25 mm dynamic load capacity: NTN NU215G1C3 Single row Cylindrical roller bearing

75 mm x 130 mm x 25 mm dynamic load capacity: NTN NU215G1C3 Single row Cylindrical roller bearing

-

30 mm x 62 mm x 16 mm da min SNR N.206.E.G15 Single row Cylindrical roller bearing

30 mm x 62 mm x 16 mm da min SNR N.206.E.G15 Single row Cylindrical roller bearing

-

25 mm x 62 mm x 17 mm Category NTN NU305ET2XC3 Single row Cylindrical roller bearing

25 mm x 62 mm x 17 mm Category NTN NU305ET2XC3 Single row Cylindrical roller bearing

-

90 mm x 160 mm x 40 mm Nlim (oil) NTN NJ2218C3 Single row Cylindrical roller bearing

90 mm x 160 mm x 40 mm Nlim (oil) NTN NJ2218C3 Single row Cylindrical roller bearing

-

110 mm x 200 mm x 38 mm Profile NTN NJ222G1C3 Single row Cylindrical roller bearing

110 mm x 200 mm x 38 mm Profile NTN NJ222G1C3 Single row Cylindrical roller bearing

-

70 mm x 125 mm x 24 mm Separable NTN N214C3 Single row Cylindrical roller bearing

70 mm x 125 mm x 24 mm Separable NTN N214C3 Single row Cylindrical roller bearing

-

60 mm x 110 mm x 28 mm Minimum Buy Quantity NTN NU2212ET2 Single row Cylindrical roller bearing

60 mm x 110 mm x 28 mm Minimum Buy Quantity NTN NU2212ET2 Single row Cylindrical roller bearing

-

Pu ZKL NU226 Single row Cylindrical roller bearing

Pu ZKL NU226 Single row Cylindrical roller bearing

-

130 mm x 280 mm x 93 mm Min operating temperature, Tmin NTN NJ2326C3 Single row Cylindrical roller bearing

130 mm x 280 mm x 93 mm Min operating temperature, Tmin NTN NJ2326C3 Single row Cylindrical roller bearing

-

50 mm x 110 mm x 27 mm d NTN NU310ET2XC3 Single row Cylindrical roller bearing

50 mm x 110 mm x 27 mm d NTN NU310ET2XC3 Single row Cylindrical roller bearing

-

80 mm x 140 mm x 33 mm rs min NTN NUP2216ET2XU Single row Cylindrical roller bearing

80 mm x 140 mm x 33 mm rs min NTN NUP2216ET2XU Single row Cylindrical roller bearing

-

75 mm x 130 mm x 25 mm Da max NTN NUP215U Single row Cylindrical roller bearing

75 mm x 130 mm x 25 mm Da max NTN NUP215U Single row Cylindrical roller bearing

-

35 mm x 72 mm x 17 mm Max operating temperature, Tmax NTN NUP207ET2XC4U Single row Cylindrical roller bearing

35 mm x 72 mm x 17 mm Max operating temperature, Tmax NTN NUP207ET2XC4U Single row Cylindrical roller bearing

-

90 mm x 160 mm x 40 mm da max NTN NU2218ET2X Single row Cylindrical roller bearing

90 mm x 160 mm x 40 mm da max NTN NU2218ET2X Single row Cylindrical roller bearing

-

30 mm x 72 mm x 27 mm Characteristic outer ring frequency, BPF0 NTN NU2306ET2X Single row Cylindrical roller bearing

30 mm x 72 mm x 27 mm Characteristic outer ring frequency, BPF0 NTN NU2306ET2X Single row Cylindrical roller bearing

-

75 mm x 160 mm x 37 mm d NTN NJ315C4 Single row Cylindrical roller bearing

75 mm x 160 mm x 37 mm d NTN NJ315C4 Single row Cylindrical roller bearing

-

100 mm x 215 mm x 47 mm Dynamic load, C NTN NU320C3 Single row Cylindrical roller bearing

100 mm x 215 mm x 47 mm Dynamic load, C NTN NU320C3 Single row Cylindrical roller bearing

-

45 mm x 85 mm x 19 mm Nlim SNR NUP209EG15J40 Single row Cylindrical roller bearing

45 mm x 85 mm x 19 mm Nlim SNR NUP209EG15J40 Single row Cylindrical roller bearing

-

45 mm x 100 mm x 25 mm Brand NTN NU309G1C3 Single row Cylindrical roller bearing

45 mm x 100 mm x 25 mm Brand NTN NU309G1C3 Single row Cylindrical roller bearing

-

60 mm x 110 mm x 28 mm B NTN NU2212ET2XC3 Single row Cylindrical roller bearing

60 mm x 110 mm x 28 mm B NTN NU2212ET2XC3 Single row Cylindrical roller bearing

-

60 mm x 130 mm x 46 mm d NTN NU2312ET2 Single row Cylindrical roller bearing

60 mm x 130 mm x 46 mm d NTN NU2312ET2 Single row Cylindrical roller bearing

-

35 mm x 72 mm x 23 mm D NTN NUP2207ET2X Single row Cylindrical roller bearing

35 mm x 72 mm x 23 mm D NTN NUP2207ET2X Single row Cylindrical roller bearing

-

60 mm x 130 mm x 46 mm Category NTN NJ2312ET2XC3 Single row Cylindrical roller bearing

60 mm x 130 mm x 46 mm Category NTN NJ2312ET2XC3 Single row Cylindrical roller bearing

-

100 mm x 215 mm x 47 mm dc min NTN NJ320EG1C3 Single row Cylindrical roller bearing

100 mm x 215 mm x 47 mm dc min NTN NJ320EG1C3 Single row Cylindrical roller bearing

-

55 mm x 100 mm x 25 mm Mass (without HJ ring) NTN NU2211EAT2X Single row Cylindrical roller bearing

55 mm x 100 mm x 25 mm Mass (without HJ ring) NTN NU2211EAT2X Single row Cylindrical roller bearing

-

D ZKL NU307E Single row Cylindrical roller bearing

D ZKL NU307E Single row Cylindrical roller bearing

-

100 mm x 215 mm x 73 mm E NTN NJ2320C3 Single row Cylindrical roller bearing

100 mm x 215 mm x 73 mm E NTN NJ2320C3 Single row Cylindrical roller bearing

-

60 mm x 110 mm x 22 mm Dynamic load, C NTN NJ212ET2XC4 Single row Cylindrical roller bearing

60 mm x 110 mm x 22 mm Dynamic load, C NTN NJ212ET2XC4 Single row Cylindrical roller bearing

-

90 mm x 160 mm x 40 mm Nlim (oil) NTN NJ2218EG1 Single row Cylindrical roller bearing

90 mm x 160 mm x 40 mm Nlim (oil) NTN NJ2218EG1 Single row Cylindrical roller bearing

-

25 mm x 52 mm x 15 mm overall width: NTN NJ205EG1C3 Single row Cylindrical roller bearing

25 mm x 52 mm x 15 mm overall width: NTN NJ205EG1C3 Single row Cylindrical roller bearing

-

45 mm x 85 mm x 23 mm da max NTN NU2209C3 Single row Cylindrical roller bearing

45 mm x 85 mm x 23 mm da max NTN NU2209C3 Single row Cylindrical roller bearing

-

90 mm x 190 mm x 43 mm ra max NTN NJ318C5 Single row Cylindrical roller bearing

90 mm x 190 mm x 43 mm ra max NTN NJ318C5 Single row Cylindrical roller bearing

-

60 mm x 110 mm x 28 mm Mass (without HJ ring) SNR NUP.2212.E.G15 Single row Cylindrical roller bearing

60 mm x 110 mm x 28 mm Mass (without HJ ring) SNR NUP.2212.E.G15 Single row Cylindrical roller bearing

Two-Row Cylindrical Roller Radial Bearings FAQS

QWhat is TWO-ROW CYLINDRICAL ROLLER RADIAL BEARINGS?

ATimken now offers a broader range of full complement cylindrical roller bearings to meet the need for increased radial load carrying capacity by maximizing the number of rollers in a given envelope. The expanded offering includes multiple series of one-row and two-row designs starting at 100 mm bore. Size range: 100 mm bore to 2000 mm OD

QWhat are the USES of FOUR-ROW CYLINDRICAL ROLLER RADIAL BEARINGS?

AFour row cylindrical roller bearings mainly bear radial and axial combined load. The bearing capacity depends on the raceway angle of the outer ring, and the larger the angle is, the greater the bearing capacity is. This kind of bearing belongs to separate type bearing, which is divided into single row, double row and four row tapered roller bearings according to the number of rows of rolling elements in the bearing. The clearance of single row tapered roller bearing needs to be adjusted by the user during installation; the clearance of double row and four row tapered roller bearing has been given according to the user's requirements when the product is delivered from the factory, and does not need to be adjusted by the user.

QWhat are the METHODS TO ADJUST THE RADIAL CLEARANCE OF CYLINDRICAL ROLLER RADIAL BEARING?

AThe commonly used methods to adjust the radial clearance of full loaded cylindrical roller bearing are as follows: 1. The side clearance of the cylindrical and elliptical bearing shells can be adjusted by manual grinding and scraping or the method of repairing and scraping after the bearing split surface is padded and turned. 2. For the top clearance of cylindrical and elliptical bearing shells, the method of manual grinding and scraping or adding pad to the bearing split when the situation allows can be used for adjustment. 3. In principle, it is not allowed to repair and adjust the clearance of multi oil wedge fixed bearing bush. If the clearance is not appropriate, replace it with a new one. 4. For multi oil wedge tilting bearing pads, it is not allowed to repair and scrape the pads. If the clearance is not appropriate, replace the tiles. For tile with adjustable thickness, the amount of tile can be adjusted by adjusting the stainless steel pad on the back of the tile or reducing the thickness of the adjustment block. Pay attention to the thickness error of the tilting bearing bush with multiple oil wedges between the blocks of the same group shall be less than 0.01mm.

QWhat is the DESIGN ATTRIBUTES of SINGLE ROW CYLINDRICAL ROLLER BEARING?

ADesigned to ISO/DIN specified interchangeable boundary dimensions where available. Sold as a completely unitized assembly. Both single row and double row products available in same size range. Standard designs use NCF, NNCF nomenclature. Full complement construction, no cage included. High capacity, but operating speed may be an issue requiring close application scrutiny. Assembly outer ring design provides significant internal axial float capability.

Hot Searches

- • Backing Housing Diameter Ds TIMKEN A-5222-WS Cylindrical Roller Radial Bearing PDF

- • Dimension S2 TIMKEN A-5230-WS Cylindrical Roller Radial Bearing PDF

- • Chamfer rsmin TIMKEN A-5232-WS Cylindrical Roller Radial Bearing PDF

- • DUR/DOR F/E TIMKEN A-5228-WS Cylindrical Roller Radial Bearing PDF

- • Width B TIMKEN A-5220-WS Cylindrical Roller Radial Bearing PDF

- • O.D. D TIMKEN A-5248-WM Cylindrical Roller Radial Bearing PDF

- • Max. Mounting Dimensions Tight Transition Fit S TIMKEN HJ-8010432 Cylindrical Roller Radial Bearing PDF

- • DUR/DOR F/E TIMKEN A-5234-WS Cylindrical Roller Radial Bearing PDF

- • Chamfer r1smin4 TIMKEN A-5236-WS Cylindrical Roller Radial Bearing PDF

- Two-Row Cylindrical Roller Radial Bearings

- Thermal Speed Ratings - Grease TIMKEN NNU4152MAW33 Two-Row Cylindrical Roller Radial Bearings

- Bore d TIMKEN NNU4156MAW33 Two-Row Cylindrical Roller Radial Bearings

- Lubrication Hole Diameter h TIMKEN NNU4988MAW33 Two-Row Cylindrical Roller Radial Bearings

- Four-Row Cylindrical Roller Radial Bearings

- O.D. D TIMKEN 250RY1681 Four-Row Cylindrical Roller Radial Bearings

- Chamfer r1smin2 TIMKEN 863RX3445A Four-Row Cylindrical Roller Radial Bearings

- Width C TIMKEN 690RX2965 Four-Row Cylindrical Roller Radial Bearings

- Cylindrical Roller Radial Bearing

- Chamfer rsmin TIMKEN NNU49/900MAW33 Cylindrical Roller Radial Bearing

- Thermal Speed Ratings - Oil TIMKEN NNU49/710MAW33 Cylindrical Roller Radial Bearing

- Bore d TIMKEN 330RX1922 Cylindrical Roller Radial Bearing

- About Us

- Company Profile

- Contact Info

- Site Map

- Sitemaps